Centrifugal Products History (1955-Today)

In 1955, Joy Manufacturing Co. consisted of only four engineers. Their office, located above a hardware store in Western New York, was the scene where they drafted designs of various types of turbo-machinery. In short time, the company purchased land in Cheektowaga, NY which became the site of their Research and Development facility. From 1955-1960, the four engineers designed, developed and experimented with gas turbines, steam turbines, axial flow compressors, in-line centrifugal compressors and integral gear centrifugal compressors.

After five years of experimentation, Joy Manufacturing Co. narrowed its focus on the design and manufacturing of an integral gear centrifugal compressor, and the MSG (multi-staged gear) models were introduced to the market. These models were primarily sold for plant air applications. Throughout the 1970’s, the company experienced a significant amount of growth domestically. During this time, Joy Manufacturing discovered a market niche and began to engineer custom compressors for refinery applications and the air separation industry.

The 1980’s signaled rapid changes and new development for Joy Manufacturing. These changes included the development and introduction of a low cost plant air compressor, the utilization of computer-based design software and a substantial manufacturing facility expansion.

In 1987, Joy Manufacturing Co. was acquired by Cooper Industries, and the Cooper Turbo-Compressor division was formed. This acquisition marked the end of the JOY name and kicked off an era of extensive new product development. As a result of substantial investments, new manufacturing tools were purchased, test facilities were enhanced, and computer equipment was upgraded. These improvements gave way to the creation of the TurboAir 2000 plant air compressor and new high-performance MSG compressors for the air separation industry.

Over 50 Years, Over 12,000 Compressors

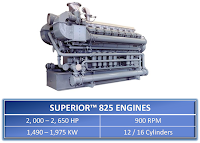

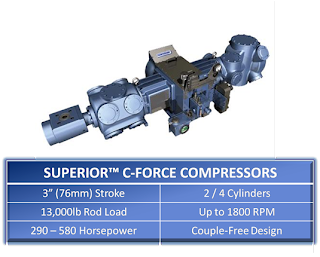

Cameron, formerly the Joy Manufacturing Company and Cooper Turbocompressor, has been a leading global manufacturer of centrifugal compressors since 1955, when the Joy Manufacturing Company began operations in, Buffalo New York. Our Turbo-Air (TA) compressor line operates up to 12,000 hp and 1,000 psig and is designed to fulfill your standard plantair needs that reside in the 600 CFM to 35,000 CFM range. Our MSG (Multi-Stage Geared) compressors are appication engineered and operate up to 20,000 hp and 1,000 psig and are designed for a wide flow range, 600 - 90,000 CFM. Our centrifugal products aftermarket team completes our product offering and is geared toward providing parts and services fo all your compressors, not just Joy compressors or those produced by Cameron.

For more information about our services, please visit our website at:

www.c-a-m.com/cs

You can follow Cameron's Compression Systems on Twitter at:

http://twitter.com/CameronCS

Join the Cameron's Compression Systems group on Linked-In at:

http://www.linkedin.com/groups?gid=2368342&trk=hb side g

Please join us on Facebook at:

http://www.facebook.com/home.php#/pages/Camerons-Compression-Systems-Group/159270207592

Check out our channel on YouTube at:

http://www.youtube.com/user/CameronCSGroup

Cameron's Compression Systems Group on Wikipedia:

http://en.wikipedia.org/wiki/Compression_Systems

Check out our Google Homepage at:

http://www.google.com/profiles/CameronCSGroup